Custom Case Printing Service

Elevate your hard cases with our specialized printing process, designed to showcase custom brand logos with precision and vibrancy.

NANUK CUSTOM LOGO PRINTING

Advanced Logo Printing on Hard Cases

Utilizing state-of-the-art techniques, we ensure that every logo is rendered with clarity and durability, making your case not just a protective shield, but also a statement of brand identity. Experience the blend of functionality and branding finesse with our bespoke printing solutions.

01

Select Your Case

Case selection is the first step in the printing process. Depending on your project requirements, you may need a case that’s tough and waterproof with a lifetime warranty—NANUK is the case you need. Looking for something stylish and affordable? Our Designer series may be the way to go. Once the case is chosen, the final step in the selection process is to decide on a color.

02

Send us your artwork

Our team of graphic designers will create a virtual layout of your logo on the case in the chosen color for your review. This digital proof is a great way to visualize your artwork on the case before approving for production.

03

We send you a digital proof

Send us your logo along with size, color and positioning requirements. To prepare your logo for print we require artwork in vector format such as native .AI or .EPS files. JPEG and other pixel type images cannot be used. Size and location can be indicated either by a drawing or simply be described in an email (templates are available for all cases). If your logo requires a custom color, simply provide us with the Pantone color code and we could produce a perfect match.

04

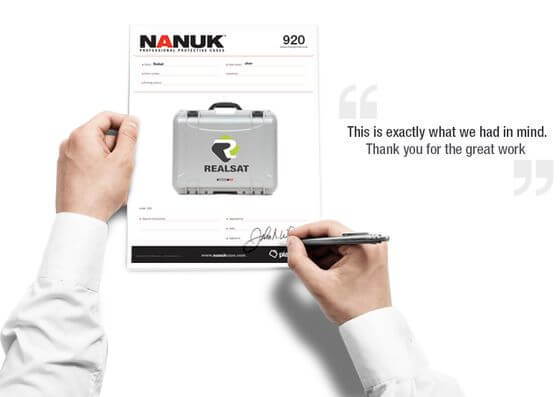

You approve the digital proof

Your Sales Representative will send you the digital proof by email for your review and approval. If the artwork layout is to your satisfaction, simply sign and return the document to proceed to production. If changes are required, we will modify the digital proof and resend for final approval.

05

We start production

Once the artwork is approved, we can move towards production. During this phase, the films required for printing are prepared and the colors are precisely mixed to match your specifications. Our specialized equipment ensures that every case is printed accurately with the correct positioning, color, and sizing requirements.

06

Quality Control

The printing process is constantly monitored to ensure consistent quality throughout the production cycle. Important elements checked during the QC process include: color matching, logo size, and placement, as well as coverage and opacity. Our strict document control process ensures that all unique specifications to your project are clearly indicated to ensure that each production meets your expectations.

07

Finished Product

Once the artwork is approved, we can move towards production. During this phase, the films required for printing are prepared and the colors are precisely mixed to match your specifications. Our specialized equipment ensures that every case is printed accurately with the correct positioning, color, and sizing requirements.

Start the Process

Elevate Your Branding Game

Stand out from the crowd with our advanced logo printing on hard cases. Whether you're a professional or an enthusiast, showcase your unique brand identity with precision and style.